您的位置: 首页 > News > Company news

What are the types of LED illuminated wine seats

2024-03-18 21:57:4187

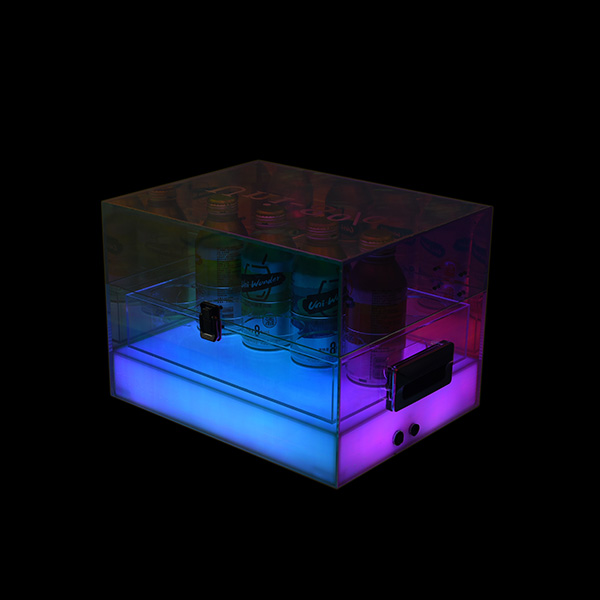

There are many types of acrylic wine stands, with different styles. Each wine stand can highlight the advantages and selling points of the wine as much as possible. Wine stands need to be carefully designed and tailored for the wine. Acrylic material has strong plasticity and can be made into circular, square, and various irregular wine stands. It can also be paired with wood and metal. Acrylic can be made into various LED luminous wine stands, which are flower wine stands or green leaves, and wine is the main, As a supplement, different wine stands are needed in different places to highlight the value of wine.

General production process

cutting

Laser cutting is a non-contact cutting method that can cut various patterns, letters, etc. The technology uses the energy released by the laser beam shining on the surface of acrylic to melt the acrylic plate. Laser cutting can accurately cut complex shaped materials, and the cut materials only need to be polished.

Punching holes

Drilling machine drilling: It is to determine the position of acrylic according to the drawing, position it, and then drill holes.

CNC punching: It is very convenient to use a machine to drill holes. We only need to use a computer to make the drawing according to the dimensions marked on the drawing and input it into the CNC machine. The machine will automatically run and work.

Hot bending

The hot bending of acrylic can be achieved through various methods, and multiple acrylic sheets can be simultaneously placed on a set of hot bending machines and shaping molds for qualitative hot bending. The vast majority of hot bends are only single or parallel hot bends, and the angle of the hot bend can be controlled according to the shaping die.

Adhesive bonding

Bonding is a very strict process that not only requires aligning the position, but also has high requirements for the firmness of the product.

assemble

Assembly goes without saying, it is the combination of multiple accessories into a complete product. After conducting a final inspection of the product quality and confirming its accuracy, the product is packaged and shipped out of the factory.

最新资讯

-

酒店发光用品:营造梦幻氛围的创意之选

酒店发光用品:营造梦幻氛围的创意之选在当今的酒店行业中,营造独特的氛围...

-

洋酒发光底座KTV发光用品

关于洋酒发光底座和KTV发光制品,以下是一些详细的信息:一、洋酒发光底座洋...

-

酒吧发光器皿摆放有什么讲究?

酒吧中的发光器皿摆放确实有一些讲究,这不仅关乎美观,也关系到整体的氛围...

-

国内亚克力制品市场分析

2024年亚克力市场发展很快,很多产品已经供不应求。而据相关报告显示未来还...

-

酒店里的发光用品是用什么材质做的?

酒店里的发光用品材质多种多样,以下是一些常见的材质及其特点:亚克力:透...

联系我们

24小时服务电话18516696204 / 13166486206

— 加微信直接沟通